Why Should You Buy Our Tray Packaging?

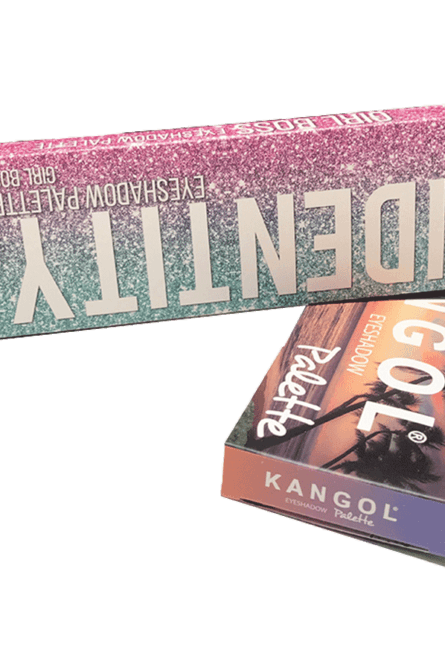

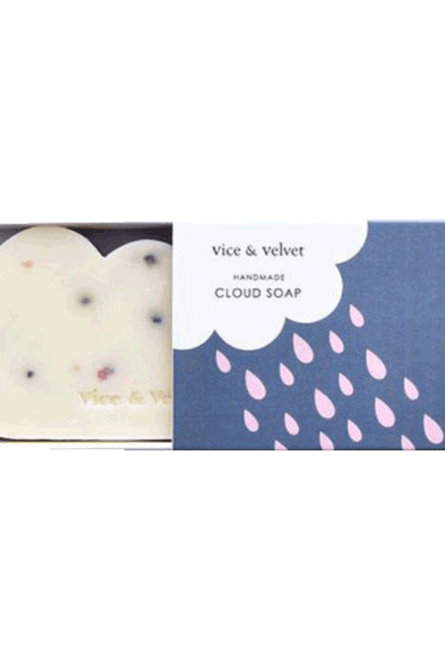

Add a touch of sophistication to your custom boxes with tray packaging. They look good and do what they're supposed to. This gorgeous sleeve can also use as a cover for the underlying tray. This distinctive custom packaging is ideal for displaying and storing confections, CBD products, and other merchandise. If you've been waiting to place an order with Packaging Bee, now is the moment to do so. The use of custom tray packaging is a very efficient method of advertising and marketing your product.

Make Your Brand Stand Out With Packaging Tray

Do you need your product to be more noticeable in a crowded marketplace?

Consumers depend on retailers to provide them with their expensive goods in sturdy, aesthetically pleasing packaging tray. The use of a custom tray and sleeve boxes is a very efficient method of advertising and marketing your product. As long as they suit the item, they can manufacture in any form or style.

These solid boxes can be cut to any size to accommodate your goods. This paper stock is four times as thick as the next thickest product on the market.

When you work with our company, you can have these sleeves customized to fit your needs exactly. You can boost sales and get more attention from customers by just using our simple purchasing process. The happiness of our clients is a top priority for us.

Books your orders today!

Materials That Can Use For The Tray Boxes

The choice of material has a significant role in determining the longevity of the boxes. Customers are grateful to choose the materials for their boxes carefully as a result.

The following is a list of the materials that can use to construct the box tray packaging. You are free to choose any of these items as your purchase.

- Cardboard

- Card-stock

- Kraft

- Corrugated

Cardboard and card stock are the materials that customers like the most and often request. Both of these materials are affordable and long-lasting, which will help protect the goods and tray boxes from being damaged in any manner. In addition, any form of printing may be done quickly and simply on these boxes. In addition to cardboard and paper, Kraft is also a good packaging material that you can use!

These days, everyone is aware that we are dealing with significant problems related to the environment. Hence, to stop more damage from being done to our environment, we are supplying all of our clients with material that is completely environmentally friendly.

On the other hand, if you want carton tray packaging for shipping, then corrugated is the material that is most suited to your needs.

Awesome Printing Options For Tray Boxes Wholesale

You have the choice of choosing any printing method for tray boxes wholesale;

- Offset Printing

- Digital Printing

- Flexography Printing

may also choose between two different colors for printing. When it comes to printing for packaging trays, you have the option of selecting colors using either CMYK or PMS.

CMYK is the way to go if you are looking for affordable color options. PMS is the ideal option to go with if you want to have a wider variety of color selections available to you.

On the other hand, PMS is more expensive than CMYK. Hence, regardless of the product, the custom package tray is always there to assist you in some manner.

Customization Available For Packaging Insert Trays

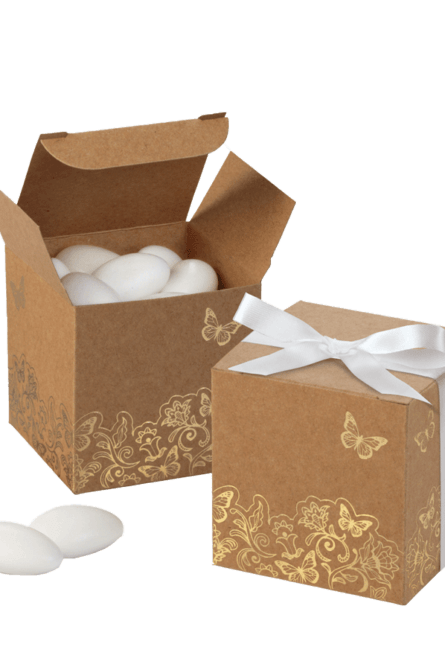

Yet, there are a great many choices accessible for the personalization of the boxes. You have the option of having windows of any sort, such as die-cut or PVC windows.

In addition, the covering is a must if you want your packaging insert trays to exude extra charm. The matte finish is an excellent choice if you're going for an appearance that's either lighter or thicker. If, on the other hand, you want your package to have a gleaming, brilliant, and sparkly appearance, then the gloss coating is the greatest option available to you. Customers seem to have a strong preference for this coating.

In addition, there are a variety of foiling available, including gold, silver, rose gold, blue, green, and so on, all of which are designed to grab the attention of customers at first look.

Embossing is another service that can provide at the customer's request and is available if they want the graphics or text on their retail boxes to elevate. Debossing, on the other hand, is the technique to use if you want the text to sunken into the surface of the material. Our customers have access on demand to a large number of additional available solutions.

-

Easy Assembling And Storage Of Food Packaging Trays

Another advantage of the display tray is that it can deliver either constructively or flat to the customer's location. After it has been completely put together, you will need to position the counters so that the product can place inside. If they are delivered flat, it is a simple process that requires only two or three steps to assemble them.

These display trays are mostly self-locking, which allows them to easily create and flattened both prior to and following their use.

The fact that these food packaging trays can fold down quickly and easily makes storage a breeze. When the display tray is not being used, you can quickly fold it down into a flat surface and store it so that it can use again and again. The best way to save money and time when ordering new things over and over again is to reuse the things you already have.

-

Size Is Everything For Cardboard Packaging Trays

The appearance of cardboard packaging trays is directly related to the size of the box! Your tray and sleeve packaging has to prepare so that it precisely fits your items and looks remarkable at the same time. Since we follow a strategy of custom manufacturing, we can make boxes in almost any size that you want.

Moreover, we manufacture boxes that are a perfect fit for your package tray products and offer protection by using die-cutting technology that is very precise.

-

Free Design Service For Package Tray Products

We have a staff of creative graphic designers that work eagerly and commit themselves to the creation of new designs that are also imaginative.

If you provide us with your own designs, our staff will assist you in getting those designs print on your packaging at no additional cost if you do so.

-

Environmentally Friendly Package Tray Material

In addition to applying environmentally friendly package tray material and cutting-edge printing processes, we also use materials that are favorable to the environment. Our in-house printing facility makes use of up-to-date printing technology. Food tray sleeves are also created from biodegradable materials, making recycling simple and beneficial to the environment.

-

100% Quality Assurance

In order to guarantee that our package tray box is of the highest possible standard, we have strict quality control systems under the direction of qualified quality check specialists.

Every kraft box that has a sleeve attached to it is subjected to strict quality control procedures to guarantee that the boxes you get are of the greatest quality and will contribute to the overall worth of your priceless product.

-

Low MOQ

You can get a paper tray for gift packaging for the precise amount that you want since we do not have a minimum order policy. This allows you to save even more money because you are only purchasing the items that you require.

Do not let the number of boxes constrain you. Whether you need one hundred or one thousand, you may get as many as you want. We treat requests for small quantities and bulk quantities equally and never compromise on the product's quality.

-

Quick Turnaround Time

With a turnaround time of only 6 to 8 working days, we have the quickest turnaround time in the business. Since we use die-cutters and the most up-to-date printing technology, we are much faster than our competitors. We promise that the whole production process will take no more than 8 business days to complete, starting from the time you accept production and ending with the delivery of your custom tray and sleeve box to your doorsteps.

Our Top Notch Line Of Tray And Sleeve Box Supply

Our company is known for providing cutting-edge printing and design services in addition to cutting-edge packaging solutions. Since we are such experts in making custom packaging boxes, we can provide our clients with cardboard food sleeves that come in a wide variety of dimensions, patterns, configurations, and theme colors.

Doing work that is of excellent quality and ensuring that the needs of our customers are met comes first for us. And at prices that are competitively inexpensive because we utilize cutting-edge technology and our team of expert printing and packaging experts. With a well-defined and effective organizational management structure.

Contact Us Now

Packaging Bee will always put the needs of the client first, above any other considerations. The orders are sent to the customer before the turnaround time, and there is no charge for shipping. You may get in touch with us if you are interested in purchasing exceptional tray packaging. Just provide us with the specifications you want for the packaging, and we will immediately begin the manufacturing process.

We are ready 24/7 to answer your queries and demands!

FAQS (Frequently Asked Questions)

Q: What Are Custom Tray Boxes?

Custom tray boxes are a type of packaging solution that features a tray or base, which is often prepared from cardboard or plastic, and a lid that fits over the top of the tray.

The package tray design is used to hold and protect the product, while the lid keeps it secure and offers additional branding opportunities.

Q: What Are The Benefits Of Using Tray Boxes?

Custom tray boxes offer numerous benefits for businesses, including improving branding opportunities, enhancing product protection, and increasing visibility on store shelves.

They are also cost-effective, easy to store and transport, and can customize to fit the unique needs of any product.

Q: What Materials Are Custom Tray Boxes Made From?

Custom tray boxes can prepare from a variety of materials, including cardboard and kraft. The choice of packaging material will depend on the specific needs of the product, as well as the desired level of protection and branding.

Q: What Is Your Minimum Order Quantity?

The minimum order quantity for custom tray boxes will depend on the manufacturer or supplier. However, our minimum order quantity is 100 boxes!