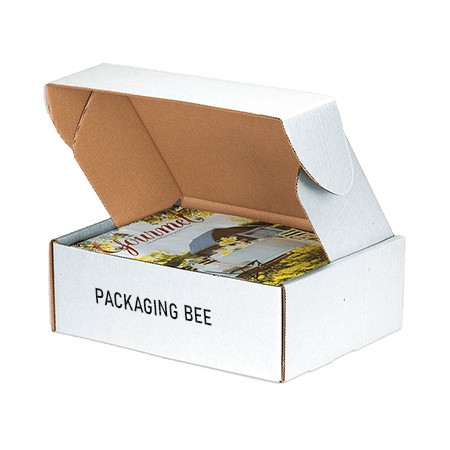

It is entirely a myth that mailer boxes are only used for mailing, shipment, and subscription purposes. Surely, the use of these boxes has advanced because today, all retailers are using them for various purposes. These retailers are currently searching for enhanced packaging that will make these mailer boxes according to their demand. The best packaging company for this purpose is Packaging Bee. It is so because we have designed Custom Mailer Boxes in such a way that you can use them for both purposes. Our primary aim is to fulfill all the requirements of our respected clients. To gratify our customers, we have introduced different impressive features for Mailer Packaging, and they will help a lot in boosting the demand for your products that you can easily place in these Mailer Boxes.

These boxes contain different properties that include helpful manufacturing styles and materials, iconic add-ons, useful printing options, and many more. At our company, you will get to avail of various discount offers.

Inspection Methods that will Make the Selection of Boxes Easy for you:

It’s a fact that all the customers love to see the outcome of their hard work. Therefore, we offer various prototypes of the boxes. Indeed, you will like to see different samples of these Mailer Packaging Boxes. Furthermore, in this method, we offer you different samples of the boxes. We offer three different types of samples, and these are Flat View, 3D Mock Up, and Physical Sampling.

The flat view is a sampling type in which we make accessible for you different 2D pictures of our Mailer Boxes Wholesale. These pictures are designed in such a way that you can see each part of the box. Furthermore, we display the images of every part of the box separately. So that you can select from them after seeing the complete structure of these boxes. After full contentment, you can let us know and we will dispatch the entire order.

3D mockup consists of the 3D pictures of these boxes. In this sample, you can see every corner and the side of the boxes. Additionally, in this sample, you can assess all the die cuts and die-lines and can see the various parts of the boxes correctly.

Most of the time, the customers don’t get satisfied with the flat view and the 3d mockup methods. Therefore, we have introduced the worthiest sampling method, and that is physical sampling. In this method, we send the ready-made sample of the Mailer Boxes. This makes the selection of the boxes easiest for the customers. In this method, they can easily see the box and then add and deduct the features according to their demand. However, it is always upon our customers to see what they like. We are here to serve you according to your needs.

Manufacturing Styles for the Convenient Assembling of the Boxes:

Indeed, the assembling of the Mailer Boxes Wholesale matters a lot, which is why we have worked keenly to offer amazing manufacturing styles. Moreover, we have introduced a die-cutting manufacturing style. This method is the most convenient and easy way to assemble your boxes because the best thing about this style is that this won’t take too much time, and you can quickly assemble it.

This method consists of the use of scoring. Scoring makes different cuts and creases on the box material. Also, contrasting panels and flaps are added to enhance the outer look of the boxes. Surely, the final assembled look of the Custom Mailer Packaging is worth-praising.

No Need to be Worried About the Safety of the Products:

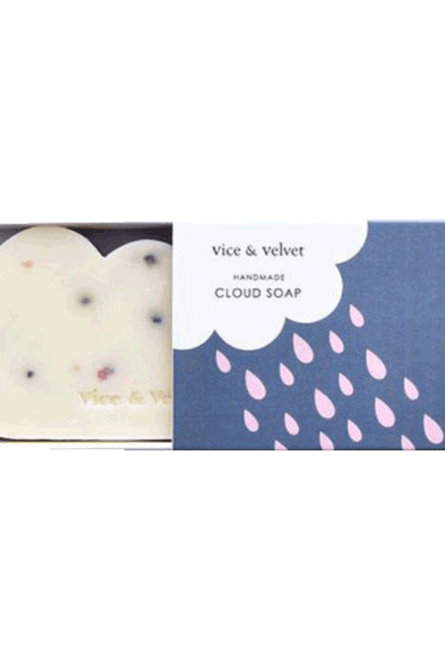

It is a fact that the safety of the products is essential. Therefore, we at Packaging Bee assure you of unimpaired and safe products. We deliver your shipment in the most reliable way. Also, you prefer those boxes that will keep your products safe from strokes and jerks. Therefore, we are here to provide you the best way from getting rid of this tension of safety of their products. We manufacture the boxes with high-quality materials that will surely fulfill the safety requirements of your products.

Additionally, we are offering four different types of materials and giving the right of selection of these materials to our customers. These materials are cardstock, Kraft, corrugated and rigid. Furthermore, all these materials are different from each other, but the one common thing among them is that they will provide the maximum amount of protection to your products.

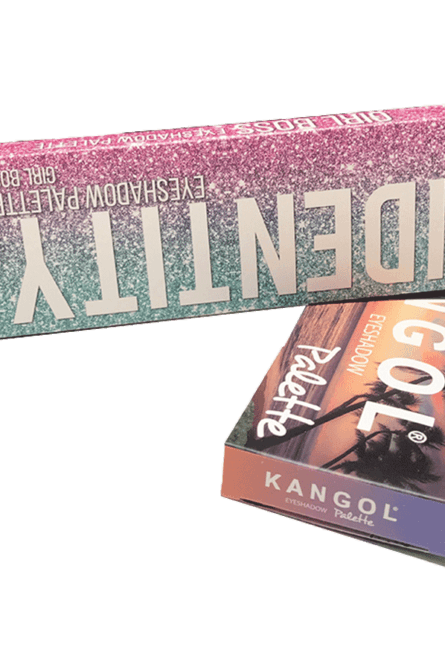

The cardstock material has the best feature, and that is the adjustable thickness. It depends on the product type that what type of the depth it needs. Furthermore, you can increase or decrease the width as per required by your products. Besides, 14pt thickness is ideal for different cosmetics and food products, while the 12pt is preferable if you are making boxes for lightweight products.

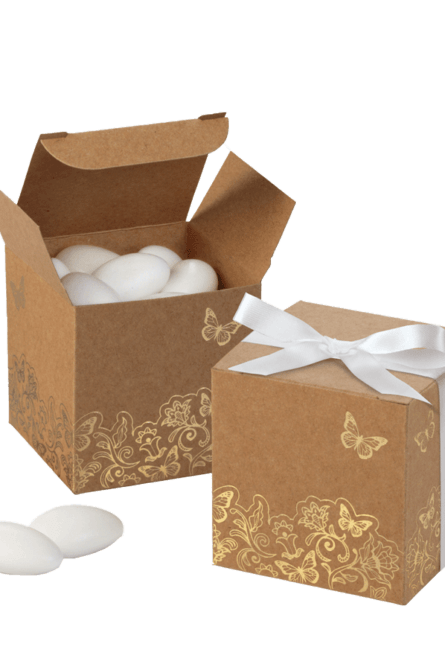

We are trying to contribute to the safety of nature, which is why we offer the kraft material for making Kraft Mailer Boxes. It has the most beneficial features for the Cheap Mailer Boxes because these are available at affordable prices and are biodegradable as well as have a variable thickness. Therefore, eco-kraft material is easily reusable. Also, if you will keep the food in it, it will be completely safe in it. Furthermore, you can change the thickness of this material according to your wish. Like, most of the time, the manufacturers show extra concern about the protection of the products. So, they can increase the thickness. We prefer its thickness between 14pt to 22pt. We believe that this thickness will give absolute safety and shield to your products.

The primary use of mailer boxes is for mailing and subscription purposes. Therefore, we have introduced corrugated material which is the best option for the shipment of products. This material comes with the thickest material. This material will save your products from getting destroyed. Furthermore, its thickness comes in flutes, and these flutes are A, B, C, E, and F. We prefer the E and F flutes for eventual safety.

The stiffest material that we offer is a rigid material. It is one of the most used materials because the products cannot get damaged in this material because of its 32pt thickness. However, it is impossible to mold it into any other shape once you have given it shape. Thus, you can now stick to the fact that rigid is the thickest material. Also, we don’t prefer this material that much because of its high prices although we can use it on the special demand of our customers.

Incredible Ranges of Sizes and Shapes:

We are offering the option of customized sizes and shapes. Like, we take orders of the boxes according to the shape of your products. Also, we give you this choice because we have seen that there are so many packaging companies that don't focus on shapes and sizes. Therefore, to facilitate our customers, we give them the right to choose the size and shape of the box as per their requirements.

Different Types of Boxes with Various Features

There are different types of White Mailer Boxes that you can choose according to your wish. These types are designed in such a way that they will undoubtedly grasp the attention of your future consumers. Furthermore, you can ask for these types in different sizes and shapes, as we have mentioned above. These types are as follow:

Firstly, The double-wall front tuck end mailer box comes with two front tuck flaps, four side closure panels, four closure panels, two side panels, two closure panels, one top closure panel, one internal front panel, and one bottom panel. These flaps and panels get together to form the final assembled box.

Secondly, we make telescopic boxes with thirteen flaps and panels that are differently distributed in the box. It’s all up to you that which type of mailer boxes you like for your products. These types are the way to represent your products most impressively. Also, help to attract the customers of products towards your brand.

Different Impressive Add-ons to Enhance the Appearance of your Boxes:

Add-ons have the power to grasp the attention of the customers towards your boxes. The add-ons that we offer include alluring foiling, mesmeric embossing and debossing, helpful die-cutting, and the fascinating Spot UV.

If we talk about the alluring foiling, then we do it on the top of the box’s surface. We offer all the colors for foiling. However, we suggest two types of foiling that include gold and silver. These are mostly used to highlight the appearance of your boxes. Like, you can use it for the stickers, logos, titles, or any other prominent thing on the Custom Printed Mailer Boxes. The best thing about this feature is that you can also use it on the whole box.

Die-cutting helps the customers in the selection of products. Also, from this window, the customers can see the product, and this makes them curious to check what is inside. We have added this option with the help of our respected buyers. Also, it's up to you whether you want to add the windows or not. There are two different types of windows, and these are PVC and die-cutting. You can see and touch the inside products from the die-cutting type. While you can only see the product from the PVC type-e as it has a transparent sheet on it that covers the product, and you can’t touch it. Thus, choose wisely and let us know.

The embossing and debossing options are also in use for the same things on which we used the foiling. Like different prominent things on the Custom Mailer Boxes with Logo. The difference between both of them is that the embossing uplifts the logos or titles from the box while the debossing imprints the logo or title into the surface of the box.

We offer Spot UV as an alternate for both coatings. We do it on the surface of the boxes to change the dull and dim appearance of the box into attractive and Colored Mailer Boxes Wholesale. Spot UV is a combination of matte a gloss coating. It covers the entire box with lusterless coverage and fills the smaller spaces with light and shine.

Why should you choose Packaging Bee?

The answer is that we are putting great efforts to serve our respected customers most appropriately. Furthermore, we understand all the needs demands of the manufacturers of the products. Therefore, we have added different features in our recommendation list to fulfill the expectation of the customers from us as a packaging company. Additionally, most of the time, the customers come with ideas in their mind and ask almost precisely according to them. In comparison to this, most of the customers depend on us as a matter of opinions. Hence, we have a capable designer staff that will suggest you the most incredible ideas related to the boxes.

Also, the key point about Packaging Bee is that we have affordable prices. We have designed the price structure after completing research on the affordability criteria of customers. Surely, all of you can avail of all the mentioned features of the Cheapest Custom Product Boxes. Do visit us for heartwarming results. It's our promise you won’t get disappointed. Hurry up, and place your order now.