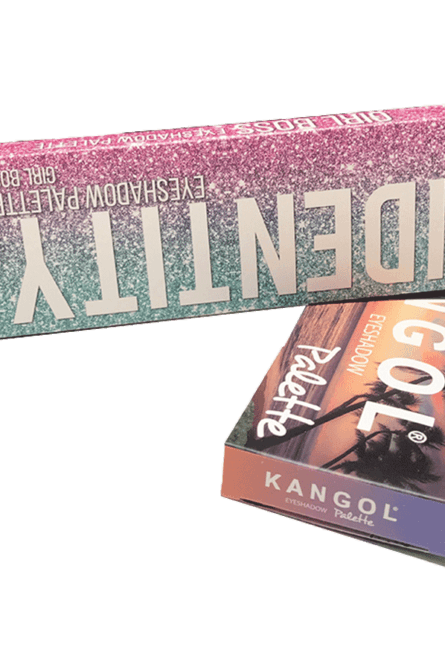

Packaging Bee USA is your one-stop shop for all of your sleeve packaging needs. The sleeve boxes we use for packaging may be made specifically for you. We can make cardboard sleeves or cut cardboard to whatever size or shape you need.

To make your color sleeve packaging, the experts at our company make use of cutting-edge printing methods and classy color models.

We also provide a wide variety of customization options, including hot stamping, spot UV, and embossing/debossing/window patching. We provide CMYK and PMS color models, as well as sample selection. Please contact us right away if you have any questions.

Why Should You Head Towards Sleeve Packaging?

These days, many items are sent in sleeve boxes, which are a novel kind of packaging. They put you in the best possible light professionally and aesthetically.

Sleeve packaging, which utilizes a sleeve slider in conjunction with a tray, provides more adaptability, as the name indicates. It's an original strategy for raising the worth of a product.

Packaging Bee provides fantastic options for personalizing your custom printed packaging sleeves. We utilize only the highest quality cardboard boxes to ensure that your things arrive safely. They're reliable enough to protect your goods throughout transit. Using top-notch components is a plus as well. You can personalize your sleeve boxes to perfection with us!

The printing company can make the boxes in the desired dimensions and hues. Energize your sleeve packaging by personalizing it with unique graphics, typefaces, and themes.

Printing on the packaging must be done with care, using only the best materials and inks. We utilize only the highest quality paper and ink.

These Custom Packaging Sleeves Helps You Make Your Brand Unique

Making money should always be the primary focus of any company. In order to advance in their respective industries, businessmen will devote countless hours and resources. They always seek new and exciting methods of packaging to attract more consumers.

Because of the high price of boxes, the custom sleeve box packaging typically ends up costing more than expected. Retailers that choose personalize packaging face an additional source of stress: unhappy end users.

Buying custom sleeve boxes in bulk is a great deal. These custom box options may help you boost your brand's value without breaking the budget.

“We know how to package better.”

These custom packaging sleeves can also serve as a cost-effective promotional tool. Paid promos and samples often cost more than they are worth in terms of increased brand awareness. When starting out, it might be difficult to choose how to prioritize spending on paid advertising among competing priorities. Advertising your company with custom sleeve boxes is a cost-effective way to get your name out there.

Brand recognition may be increased by having packaging sleeves print with your company's emblem. The unique box packaging acts as your silent brand ambassador, convincing clients to test the items, and encouraging them to purchase more via the thrilling unwrapping experience provided by the window sleeve boxes.

How To Choose The Best Material For Your Sleeve Box Packaging

It's important to use high-quality materials when creating your sleeve box packaging.

The following are some of the materials available from us;

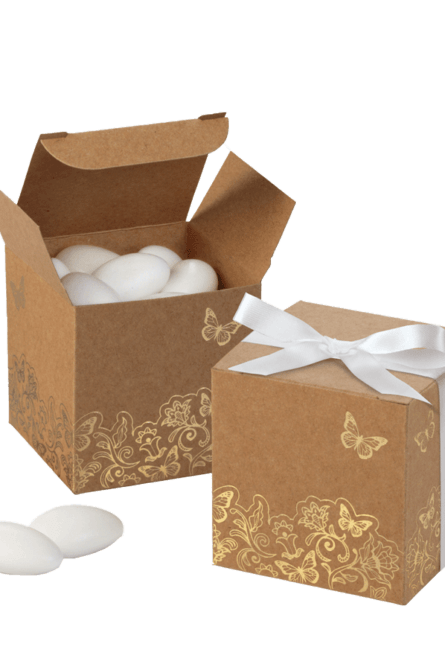

- Kraft Material

- Cardstock Material

- Rigid Material

- Cardboard Material

- Corrugated Material

It is highly recommend that you get the opinion of your packaging partner before making your final packaging material selection. That's because every substance has its advantages and disadvantages. Hence, not all materials are suitable for all brands.

Add-Ons To Make Your Paper Sleeve Packaging Really Stand Out

Modifications like this might make your paper sleeve packaging stand out from the rest. Being a wholesaler, we also deal with sleeve boxes.

The following add-ons are available from us;

- Embossing

- Debossing

- Spot UV

- Hot Stamping

- Window Patching

-

Embossing

The sleeve box will print with raised writing or a graphic. Since paper is so flexible, the whole sleeve box must be built from it for this to work. The eco friendly packaging sleeves with our imprinted logo are just one example.

-

Debossing

Unfortunately, not all designs are suitable for embossing. The debossing method has a wider range of applications and can use with various materials.

-

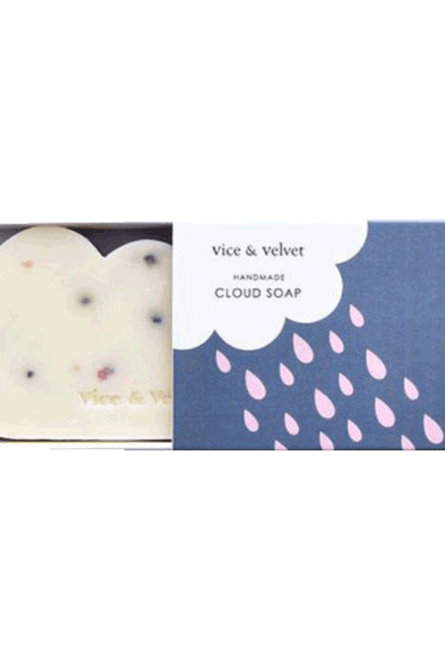

Spot UV

Adding a spot UV treatment to your wholesale sleeve boxes will give them that extra something. Its one-of-a-kind sheen will catch the eye of your buyer at first sight.

The logo's depth and dimension are emphasized by the reflective qualities of the spot UV treatment. This, however, is only achievable if the packaging sleeves for boxes are constructed from appropriate material. This can be the best option for a high-quality finish if you can't afford it or don't have time for a printing procedure.

-

Hot Stamping

It's a simple and fast strategy for making your packaging more impressive. To produce an imprint on paper, heat a die engraved with your company logo and press it with a metal stamp. Customers will be impressed, and your brand will be visible for a long time.

-

Window Patching

It is often used on custom sleeve packaging that has windows or cutouts, allowing for the inside to be a different color from the outside. In sharp contrast to the outside, this highlights your company's name or logo.

Let’s learn more about how to make packaging sleeves!

Coatings That Entice Potential Buyers

Adding finishing coatings may make your packaging sleeve printing seem more elegant and professional. We provide the following coatings for its products:

- Matte Finish

- Varnish Finish

- Gloss Finish

- Soft-Touch Finish

-

Matte Finish

The matte texture lends your custom product sleeves an air of sophistication. It can be done on paper, but it shouldn't use for anything other than handling food.

-

Varnish Finish

Polyurethane or acetate is used to create this glossy top coat. The finished carton sleeve packaging will have a glossy appearance that will help it stand out from the crowd. Many kinds of paper, cardboard, and plastic may be used.

-

Gloss Finish

Adding a glossy coating to your cheap packaging sleeves is a great way to draw attention to their rounded edges. This results in lavishness. A black gloss box with a white personalized logo, for instance, is a striking design choice.

-

Soft-touch Finish

Your packaging will have an improved exceptional experience thanks to this. Soft-touch printing on the packaging box sleeve does this. It's beautiful whether it's matte or glossy, and it can function well on its own.

Printing Methods

We provide a variety of printing options for packaging with sleeves.

- Digital Printing

- Offset Printing

-

Digital Printing

Whether you need a basic or intricate design print on your food packaging sleeves, the digital printing method can handle it. Furthermore, it can print on both paper and plastic sleeves and has a vast color range.

-

Offset Printing

The quality of an offset printout is unparalleled. Nevertheless, the economics only work out for massive production runs. Keep in mind, however, that if you need to make any modifications to the design, this printing method will just add time and money to the process.

Why Should You Choose Us?

Long-term relationships with clients are important to Packaging Bee USA. Because of all of our great traits, we rank at the top. Check out some examples:

- Timely shipping is guaranteed by our central packaging facility. We provide product packaging sleeves on short notice since we know that expanding enterprises frequently need urgent delivery.

- No die and plate charges.

- As a result of our familiarity with the constraints of corporate finances, we can provide wholesale pricing on our custom printed sleeves, making them accessible to companies of all sizes. Custom sleeve boxes might be expensive, but not with us.

- We provide packaging options that minimize your impact on the environment, giving your company a good reputation.

- The logistics industry has skyrocketed in price. We provide free domestic delivery to save our customers the time and money associated with shipping.

- We place a premium on earning our clients' confidence, which is why we tailor our box production to meet your specific needs.

When you need us, we're here for you, any time.

Do you still have questions? Get in touch with us now, and we'll do anything we can to help. Surprise your customers with sleeve packaging and watch your sales soar.