Our premium E-Liquid Packaging is now available to be shipped at your disposal. As part of our easy three-step process, we provide services that are second to none- Ever wondered how these custom product boxes are made? What are the specifications of those boxes, and are they safe to have or not? With the evolution of the CBD Industry, multiple brands use various ways to promote their products into the market. However, custom e-liquid packaging comes with a fragile factor attached with it. Durable, secure, and sturdy materials warrant the safety of these boxes.

For the intact delivery of boxes, we provide rush orders as well. Packaging Bee is one of the renowned names that have made their mark in a very short period of time. The majority of consumers buy a product solely by the way they are packed. Good packaging attracts an audience, whereas improper packaging tends to drive away users. Get a quote today and get unmatched e-liquid packaging wholesale rates.

Materials – Suitable For Any Purpose

Packaging Bee does not compromise on the quality of packaging material. Therefore, we prefer materials that are not suitable for local use but can also be shipped to distant locations with ease and intact products on your doorstep.

-

Kraft Cardstock (Eco-Friendly Stock)

We care for our environment; we care for the free oxygen we get. For this purpose, our customized e-liquid packaging can be made from Eco-Friendly Kraft. A recycled and biodegraded material such as Eco-Friendly Kraft has a standard range from 12pt to 14pt. Pasting is not recommended as the material is already recycled.

-

Corrugated

The corrugated material consists of a fluted corrugated sheet and one or two flat linerboards; these are made of paperboard and cardboard and are strong enough to carry weighted products.

-

Card Stock

Also known as Cover Stock and pasteboard, Card Stocks are reasonable packaging material. They are thicker than standard paper. Cardboard Stock can be ranged from 12pt to 28pt. We recommend pasting if the mark crosses 14pt. For instance, for 16pt, two 8pt cardboard stock materials are enjoined.

Custom printed e-liquid packaging comes in every shape and size, depending on your product specification and requirement. How you want your box to be manufactured is up to you, Packaging Bee gives its clients all manufacturing styles’ choices such as:

- Flat Box

- Gluing

- Perforation

- Scoring

Customizable in All Sizes, Designs, and Dimensions – Perfect Looking Product

When designing an e-liquid packaging box, it is essential to understand the target audience. What are the needs of the audience that you will be keeping in mind while manufacturing the package for them? Packaging Bee understands its consumers well. They make sure businesses’ needs are met wholly and carefully. Following designs are available for you to select:

-

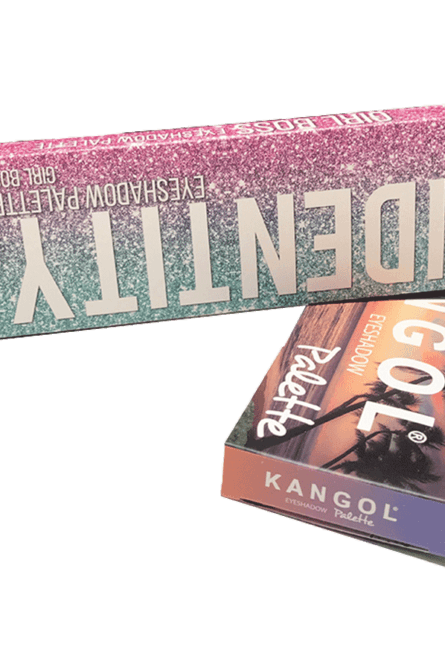

Sleeve Box

Sleeve Box packaging is a unique way of delivering your product. They are available in custom sizes, and a number of sleeves can be added to the box to promote your product. Additional stylish printing on these boxes can be valuable for showcasing products.

-

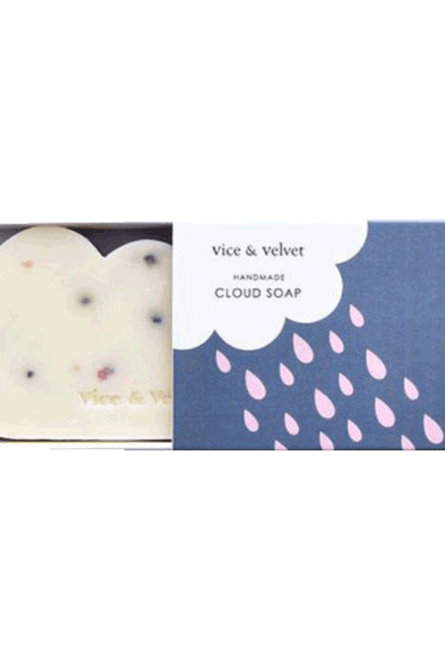

Tuck-end Box

Most popular type of box for e-liquid packaging. It brings a luxury printed packaging to the product. The standard kind of tuck-end for custom printed e-liquid packaging includes the Straight Tuck-end box, which has tuck closure at the top and bottom of the box. Our tuck-end boxes have a clear display window for perfectly showcasing your product.

-

Display Boxes

For a perfect impact on your customers in malls, retail stores, and convenience stores, display boxes are your answer for all questions. These well-crafted die-cut window display boxes in desired shapes and sizes proves to be a valuable asset in promoting your product.

-

Mailer Boxes

Perfect for shipping, mailer boxes are in huge demand because of their wide variety of purposes and ease with custom size and designs. All you have to do is select a size, quantity, and start designing your box. Moreover, our clients are given the choice of choosing manufacturing paper, option of adding inserts, coating and manufacturing style; to make your product stand out in the crowd.

-

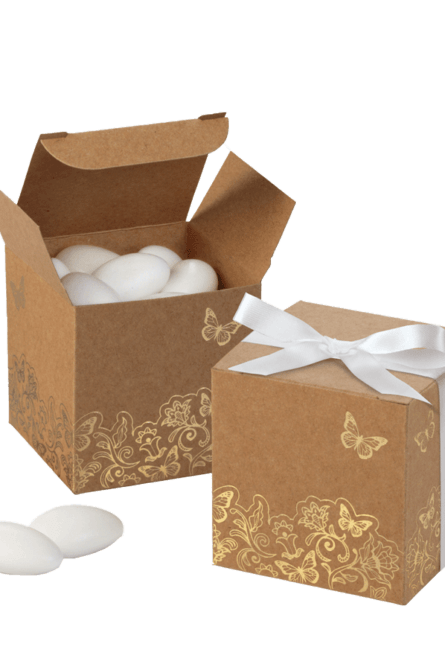

Seal end Boxes

Protecting as well as providing charm to your product, seal end boxes are one of our top recommendations. They are easy to assemble and can carry a heavy load. Suitable for shipping to your loved ones on special occasions. Packaging Bee makes it easy for clients to custom design and size their boxes to meet the target audience.

Coating – For a Lasting Impression

Coating plays an important role in making your product stand out in the market. With accurate coating, correlating with the product design, box size, and dimensions, there are many chances of making your product ‘pop’ in the crowd.

-

Gloss Coating

In simple words, Gloss Coating is the one that shines in the light. Gloss coating provides high levels of gloss, with up to 90% surface reflectance of 60°, as well as good scuff resistance. Gloss coating is mostly suitable for folding cartons.

-

Matte Coating

Matte coating makes ‘metallic plastic’ a reality. It gives a soft satin sheen to the packaging. Matte coatings utilize less binder agents, which produce less cohesive material and a powdered texture. Packaging Bee gives you the choice of Gloss and Matte coating, depending upon your needs and circumstances.

Add-Ons For Extra!

Do you want your to be extra for a better-looking packaging? If yes, then you can utilize the following Add-ons:

-

Spot UV

Spot UV refers to the application of Ultra-Violet coating to a specific area. It is a creative way of adding depth and contrast through varying levels of sheen and texture.

-

Foil Stamping

In foil stamping, a metallic paper is applied by heat and pressure. It is one of the simplest ways to give a decorative touch to the product. Foil Stamping is opaque and does not contain any ink.

-

Die-Cutting

Die-cutting refers to the act of using a sharp die to cut substrates into various shapes. It is an automated process which allows multiple pieces to come into the same shape and pattern into an efficient manner.

-

Embossing and Debossing

Embossing and Debossing give the product a new dimension by raising or lowering a particular area on the packaging. Embossing means carving logos, whereas Debossing imprints titles into the packaging.

Printing – Various Options For Everyone

At Packaging Bees, our clients can select a suitable type of printing. We offer the following printing options:

- Digital Printing

- Offset Printing

- Flexography Printing

Color Models – Correlate With The Product

Color combination plays a vital role in promoting your product. Selection of bright colors dictate the future of packaging and in turn, your business. We offer the following color models to our clients:

-

CMYK

CMYK color model includes Cyan, Magenta, yellow, and black colors. These four colors are mixed to give different colors. This is an inexpensive approach.

-

PMS

PMS stands for Pantone Matching System. In this model, the colors are not mixed instead are absolute through separate color codes.

Prototypes – How would you like it?

Do you wish to see our premium boxes and other packaging stuff? That’s alright; we provide the sample through one of the following means; the choice is always is yours:

- Flat View.

- 3D inspection.

- Physical Sampling.

Why Should Packaging Bee Be Your First Choice?

There are numerous reasons why Packaging Bee can be your go-to-stop. To make the long thing short, Packaging Bee is 24/7 available at your service, keeping experts handy and eyes open for updates. What else would you like to have? Call our executives anytime and aid your packaging headache.