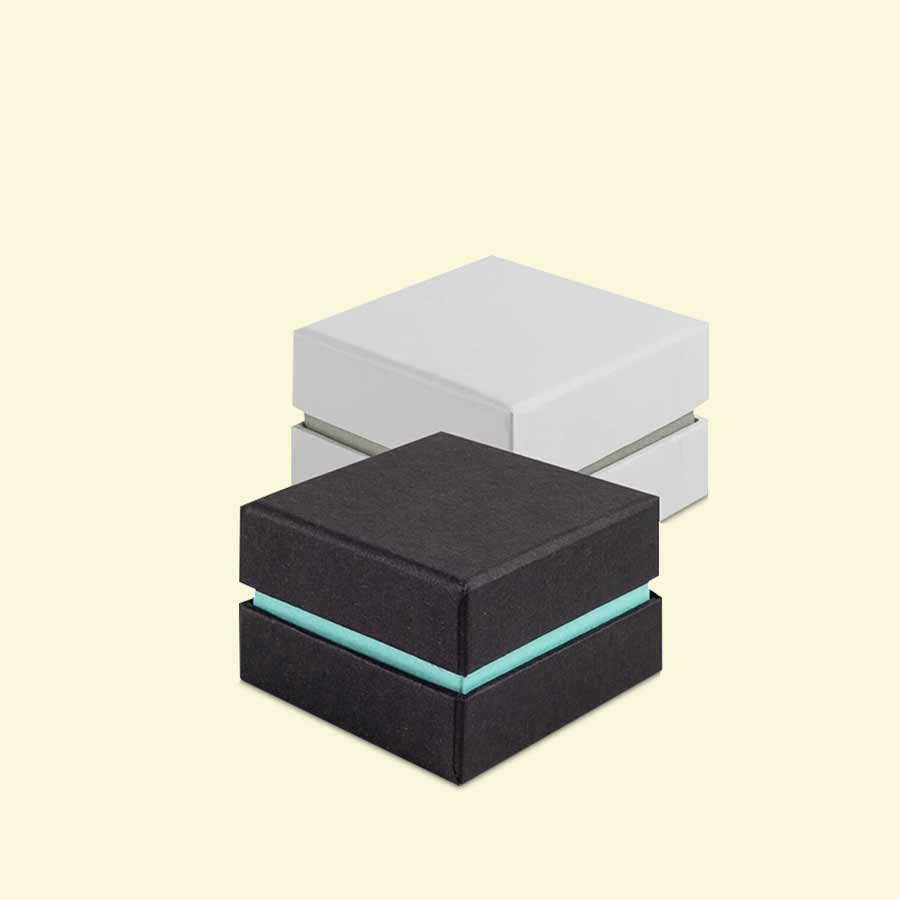

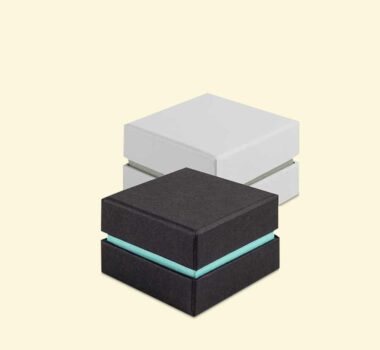

Are you looking for custom rigid gift boxes that are crafted as per your needs? Your search ends with Packaging Bee. We can craft rigid gift boxes with lids in custom shapes and sizes while catering to your branding and marketing needs as well. Furthermore, we rely on premium-quality packaging material to create rigid gift boxes.

Apart from that, we offer different printing techniques, color models, and a variety of customizations. You can opt for various combinations of add-ons and different finishing coats to create unique custom rigid gift boxes. Last but not least, we also offer sampling options. So, get in touch with us today and let’s take your brand to the next level!