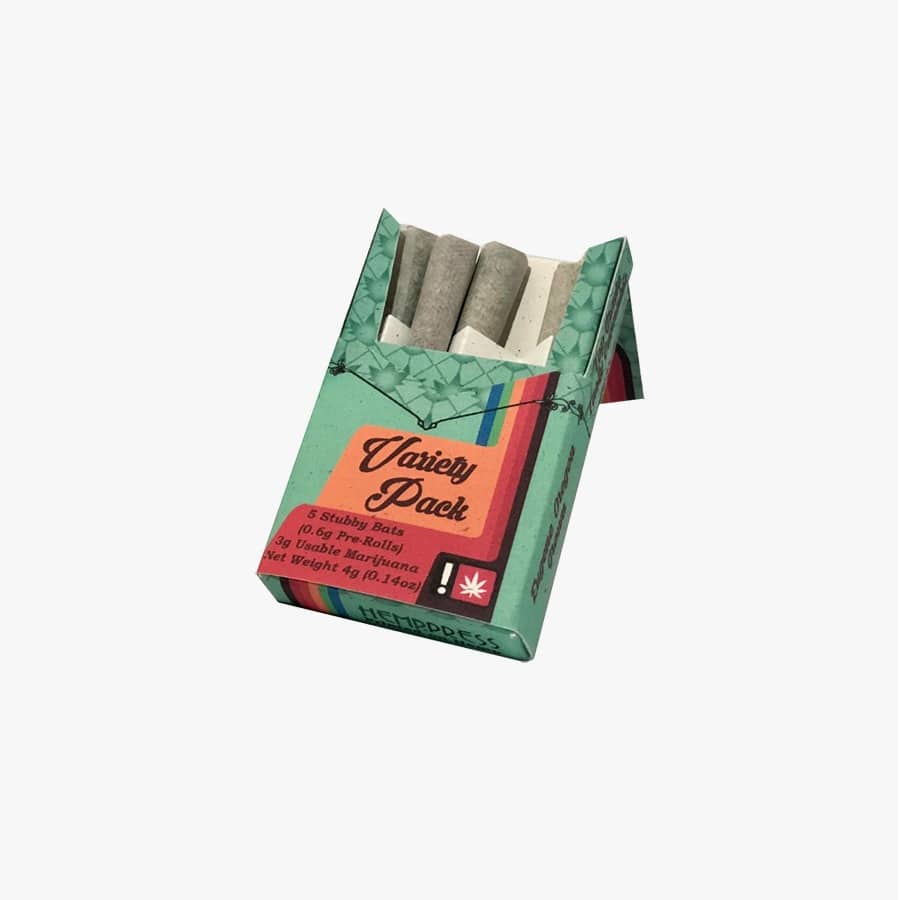

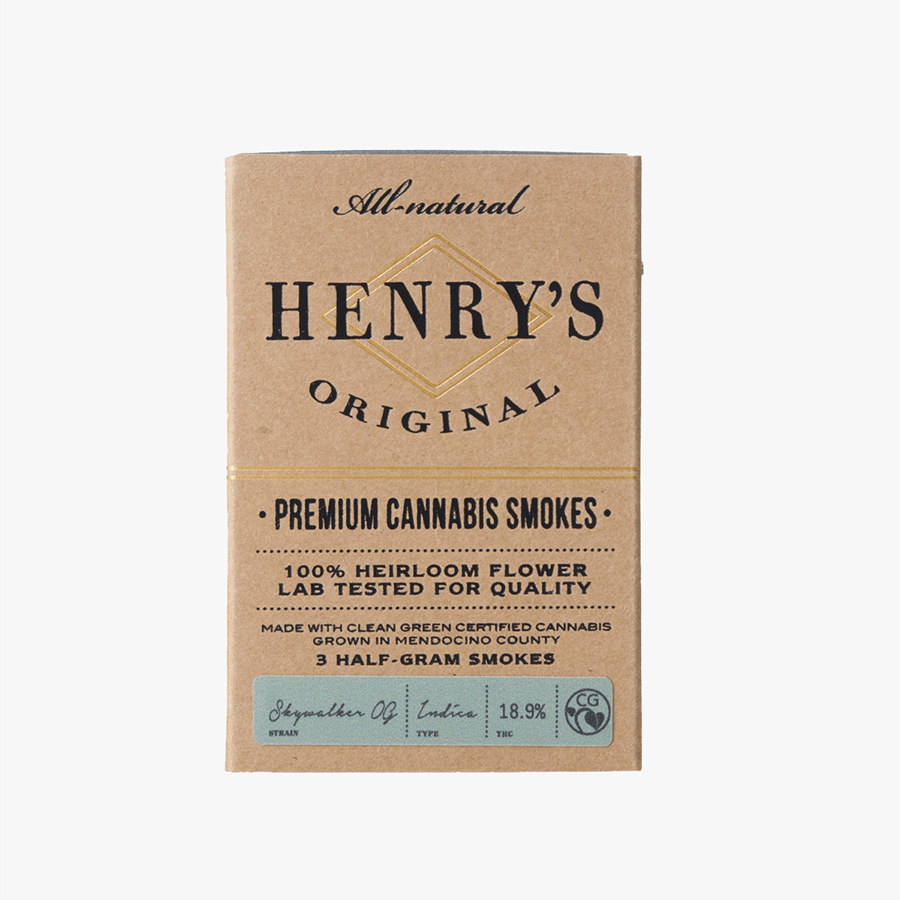

If you are concerned about the safety of your Prerolls and in search of sufficient packaging, the best platform is Packaging Bee. We are here to serve you by providing the best packaging options for your Prerolls. The primary purpose of our company is to provide such type of packaging to our customers that would give the tantalizing and the defensive look to their pre-rolls.

Prerolls Packaging has all the main features that the customers want for the Prerolls product. Prerolls Packaging Boxes are made from such materials that would give the eventual protection to the Prerolls product that the customers would keep in it. The best part about these boxes is that they come in different styles that would give an impressive look to your packaging. Our company is providing all the rights of the selection of the features of the Custom Prerolls Packaging to our customers. We try our best to serve our customers most effectively. This clarifies that our priority is our customers.