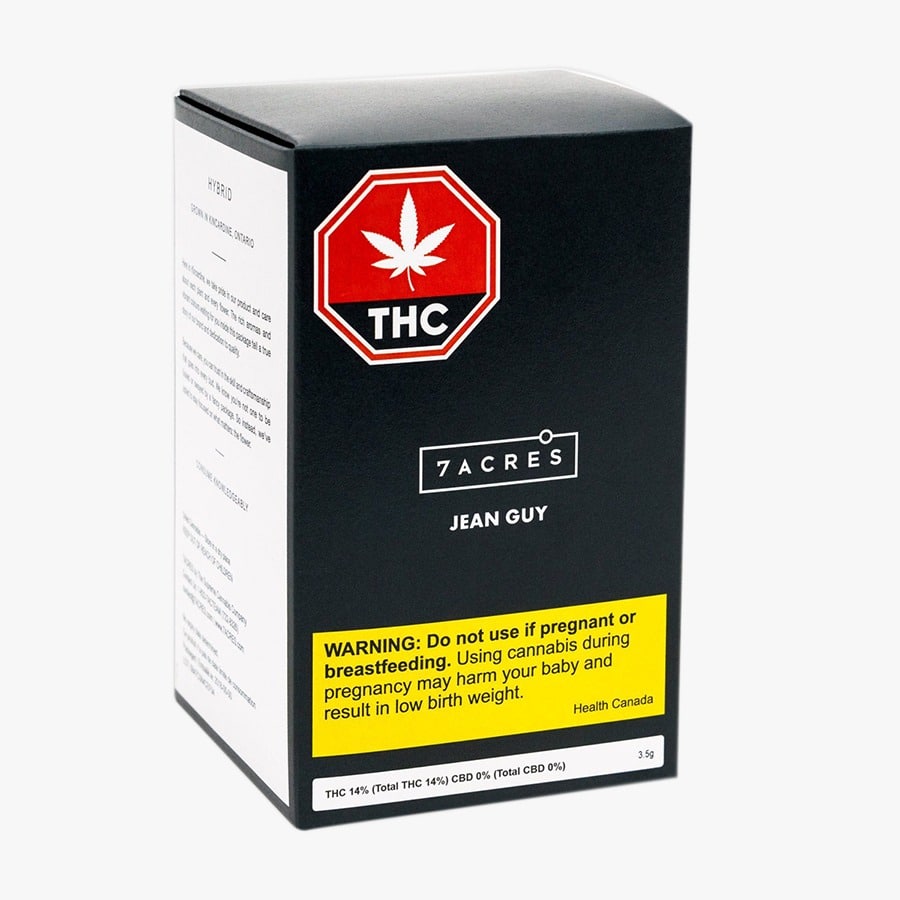

With the increasing demand of marijuana in the market, the high-end boxes are all you need to stand out in this competitive market. Packaging Bee provides custom printed marijuana boxes to create brand loyalty among new as well as regular customers. Glorify your product and let it communicate with the people visually. It will help you in getting uncountable benefits, which would be impossible by ordinary and plain boxes. Get your marijuana tinctures in high-end boxes, which will ensure the safety of your product.

Ship your marijuana potion with marijuana boxes wholesale with inserts safely to prevent the future hassle. Mesmerize your customers by the eye-catching designs and accurate dimensions of your marijuana boxes. To imply the first positive impression on customers, custom marijuana boxes are best as they are designed in custom shape, size and design, and structure. Besides we ship custom marijuana boxes free of cost throughout the USA.