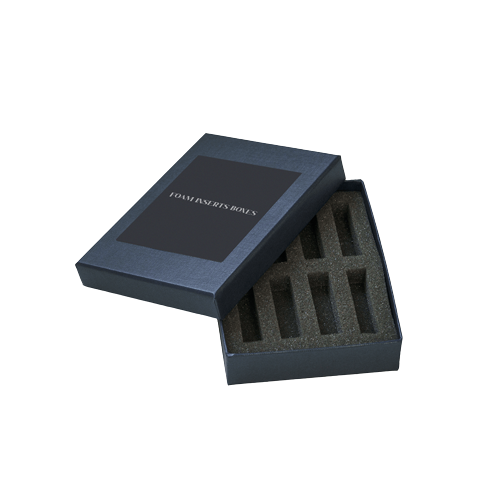

Are you tired of packaging products not knowing whether they'll be safe or not? Well, the time has come to rid yourself of that worry. Packaging Bee offers custom foam inserts for boxes that help you outgrow that worry and meet any product protection needs.

However, that is not all. Our custom foam box inserts can make your products look more professional and attractive. Our foam inserts are made using the highest quality raw materials. Furthermore, you can customize them to any shape and size. If foam is not your thing, we also offer other materials making our custom inserts for boxes truly versatile.

So contact our experts today and let us turn your worries into a thing of the past!