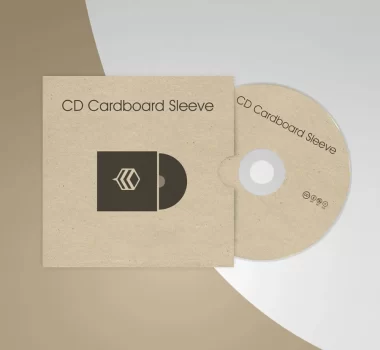

What Are CD Sleeves?

A CD sleeve is like a cover with a compact disc in place, preventing scratching, dust, and damage. Usually available in many forms create from paper, plastic, or cardboard, a CD sleeve is a lighter and cheaper alternative to a jewel case.

They come in various styles, from simple paper sleeves to plastic ones with adhesive closure and even more durable ones create from cardboard with a printout design for branding or personal uses. Generally speaking, CD sleeves are utilize in mass-produced CDs, for example, promotional discs, software, or even a music album where inexpensive and space-saving covers are necessary. Moreover, they provide an ecologically friendly package as fewer materials are use than complex cases.

Uses Of CD Case Sleeves

CD case sleeves are employed for different uses. Some of the common uses of a CD sleeve include:

- Protection: These sleeves act like a buffer between the disc and the environment, thus protecting the CDs from scratches, dust, and fingerprints. This helps preserve the quality of data or media store on the disc and extend its life.

- Space-saving Storage: Sleek and flimsy, a CD sleeve is way thinner and lighter than the usual jewel cases. Because of this, sleeves are the perfect solution to organize extensive collections of CDs and fit them into a small space. Whether it involves personal collection purposes, business archives, or even promotional CDs handed out en masse, these sleeves enable you to store more discs in less space, hence becoming efficient for use at homes, offices, and shops.

- Low-cost Packaging: The sleeve is a low-cost packaging method, particularly for large-scale productions. These are use for promotional discs, software distribution, and music albums, for which cost is essential. For companies willing to give away CDs in large numbers, sleeves offer a more economical alternative to plastic cases without compromising the basic level of protection.

- Branding and Personalization: A CD sleeve is an excellent surface for branding and designing. Corporations and artists commonly use custom sleeves featuring logos, artwork, and promotional messaging. This not only adds more aesthetic value. But also reinforces brand identity. Custom sleeves are use for corporate giveaways, launching new product lines, or even launching music albums, therefore adding a personalize touch to making the product noticed.

- Eco-friendly Alternative: In today's world, where environmental impact has become a growing concern for many, paper, cardboard, or other recyclable material-based CD sleeves are an eco-friendly alternative to plastic jewel cases. Since less plastic is involved, companies and individuals alike contribute to reduced carbon footprints.

Print Your Brand Logo On CD DVD Sleeves

Printing your logo on CD DVD sleeves effectively upgrades your packaging and promotes brand identity.

A personalized touch, with a custom-designed logo on your CD and DVD sleeves, brings personalization into perspective, reinforces your brand, and gives your product a unique look. Whether for promotional CDs, software distribution, or even music albums, branded sleeves guarantee harmonious visual appeal that leaves an unforgettable mark on one's memory. This will not only make your product more presentable. But will also help increase brand visibility. Printing your logo adds professionalism, too, which may help gain customers' trust and perceived value.

Furthermore, it acts like a low-budget marketing tool with which customers can relate your logo to quality and reliability every time they use or view your CD or DVD.

Elegant Printing Options For CD Sleeves Near Me

Printing CD sleeves near me can be available in various ways, from low-cost, small-run solutions to larger volume, higher quality printing.

Herein are the most common methods for CD sleeve printing;

-

Offset Printing

Offset printing remains one of the most in-demand techniques due to its high quality and large volume production. It enables sharp, vivid colors with clear details, which is why it is ideal for intricate designs and high-resolution images.

- Benefits: It is excellent for color accuracy, suitable for large runs. And offers a wide range of finishes, such as matte, gloss, or spot UV.

-

Digital Printing

It is ideal for a digital print run when smaller runs are needed or for pieces needing urgent turnarounds. This printing technique is similar to what people do at home. But on an industrial scale, thus providing good-quality prints full of vivid details.

- Benefits: No setup fees, quicker production, ideal for complex designs and high-resolution graphics.

-

Screen Printing

Printing is a process where ink is forced through a mesh screen to carry out a design onto the material. It is good for simple designs and can work on various materials.

- Benefits: Very durable, bright prints, excellent color saturation, suitable for different surfaces & CD sleeve dieline.

-

Flexographic Printing

This printing is a high-volume printing method that uses high speeds and is generally used for packaging materials. It's well-suited for simple designs and large runs.

- Benefits: It is economical for large-quantity orders, has quicker production time. And is ideal for simple designs of custom sleeves.

-

Hot Foil Stamping

Hot foil stamping gives the CD sleeves a metallic or shiny appearance, which allows for the highlighting of selected portions of the design, such as logos or text.

- Benefits: It provides high-class and premium looks with metallic or gloss effects; it can also give a feel of tactility through embossing or debossing details.

-

Embossing and Debossing

While embossing raises the design from the surface, debossing does the opposite. Both techniques give the CD sleeve template a tactile and three-dimensional feel.

- Benefits: It gives a sophisticated and truly tactile feel and enhances the visible look by adding a three-dimensional effect.

Get Customers' Attention With Highly Exclusive Custom CD Sleeves

Wow, customers with strikingly different compact disc sleeves that protect your discs in style while making your brand even more attractive. The great custom CD sleeves can turn an ordinary disc into an unforgettable experience of your product. Make your packaging solution truly distinctive and say a lot about your brand with eye-catching graphics, distinctive shapes, or innovative materials.

Other ideas that can make your sleeve pop visually include bold colors, intricate patterns, and interactive elements of texture finishes or custom cutouts. In addition, other special design elements, such as holographic prints or embossed company logos, can add an element of premium appeal that will help increase the perceived value of your product. An eye-catching compact CD sleeve is more than just a package holding a disc inside. It forms part of your brand strategy, leaving a mark on your customers ' minds and making them eager to consume whatever it holds.

Your investment in creative, high-quality printable CD sleeves protects your product while ramping up its marketability and appeal for deeper customer connections.

CD Sleeve Dimensions

CD sleeves usually come in standard dimensions, accommodating compact discs and fitting inside various packaging systems. Well, the following CD sleeve dimensions include the following:

-

Standard CD Sleeve

- Size: 5.125 x 5.125 inches (130 x 130 mm)

- Capacity: Holds one CD or DVD

-

CD Wallet Sleeve

- Size: 5.25 x 5.25 inches (133 x 133 mm)

- Capacity: Holds one to four CDs or DVDs

-

Mini CD Sleeve

- Size: 4.75 x 4.75 inches (121 x 121 mm)

- Capacity: For mini CDs - 3-inch discs

-

DVD Sleeve

- Size: 5.31 x 7.5 inches (135 x 190 mm)

- Capacity: Accommodates one DVD or Blu-ray disc

Premium Packaging Material Choice For Printed Cd Sleeves

When choosing premium packaging material for the sleeves of your CDs, you should not compromise on durability, looks, or the impression such a thing produces. Here are some of the top choices as far as premium materials are concerned for printed CD sleeves.

-

Cardboard

The cardboard for the CD sleeves is create from high-quality material, which provides a strong and durable option. These can be finished with gloss, matte, or even a textured coating to give them that classy look. This is great for premium products and, at the same time, provides ample space for printing detailed designs or album artwork.

-

Kraft Paper

Kraft paper is eco-friendly and durable, which ensures a more natural look and feel. That would be perfect for brands that focus on sustainability since the appearance will be more organic and premium. It can easily be branded with stamps and logos or with minimalist designs accentuating the premium feel.

-

Vinyl

Vinyl sleeves are sleek, modern, and protective, offering a rich, high-gloss finish. Furthermore, vinyl is applied in special editions, lending a touch of luxury to the packaging. Premium materials raise perceived value and create an experience worth remembering while unboxing.

Get Bulk Discounts On CD/DVD Sleeves With PB

PB creates the ultimate packaging solutions and offers bulk discounts for the finest and most customized CD/DVD sleeves and packaging materials. Whether it's sleek, eco-friendly designs or premium finishes your brand needs, PB will offer various options that cater to your brand's needs.

When you order in bulk, you can assure yourself that you get top-quality products, saving you a load with competitive pricing. PB ensures that every detail of your vision is catered to, from customized size and shape to branded design and eco-friendly material. Also, our bulk discount packages allow businesses and artists alike to have professional-grade custom cardboard CD sleeves at a conveniently affordable price while never compromising on quality.

Place Your Order Today With Us

Whether you want custom CD sleeves, eco-friendly options, or bulk orders at the most unbeatable price, we at Packaging Bee have you covered.

From unique designs to high-quality material, our team of experts in the field ensures every minute detail of the product is perfectly created. Fast production, reliable customer support, and flexible options make ordering as simple as a snap. Don't wait; team up with us to take your packaging to the next level and create an impression that lasts. Place your order today and have us create it for you!