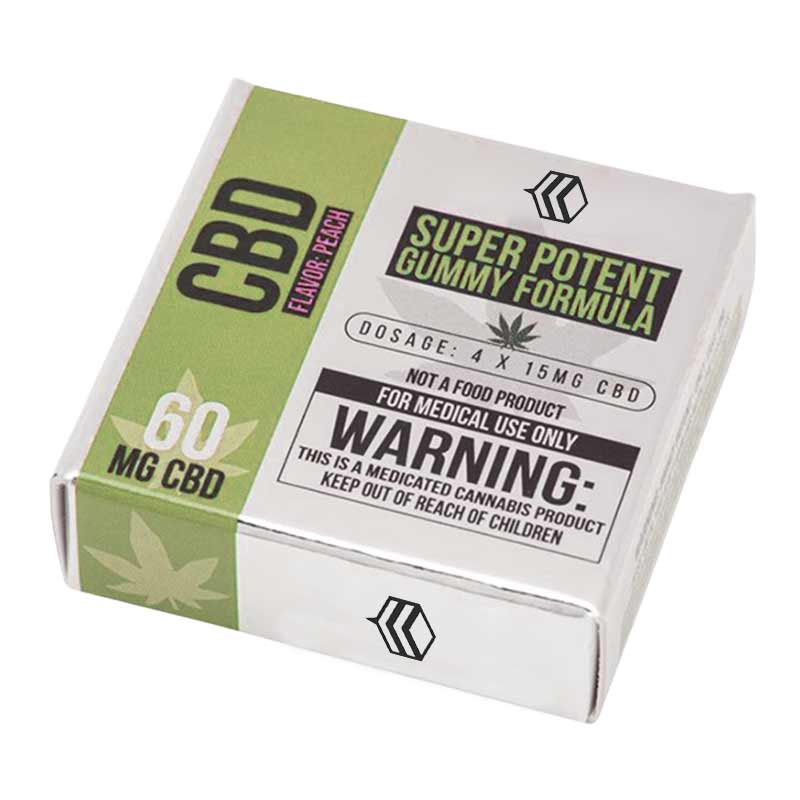

If you are tired of using low-quality packaging solutions that make your customers turn away from your CBD gummies, then you need to check out the latest collection of custom CBD gummies packaging by Packaging Bee. Made from the highest-quality paper packaging materials, our custom gummies box can not only help you protect your tasty treats but also serve as a mini billboard.

We do that by offering you incredible printing techniques that help you save costs while giving the best print quality. Furthermore, we couple that with standard color models that are perfect for creating vibrant and brand-accurate shades. Furthermore, you can make your CBD gummies packaging stand apart from the crowd using our exciting add-ons and finishing coats.

So what are you waiting for? Contact Packaging Bee today, and let's get some prototypes going.