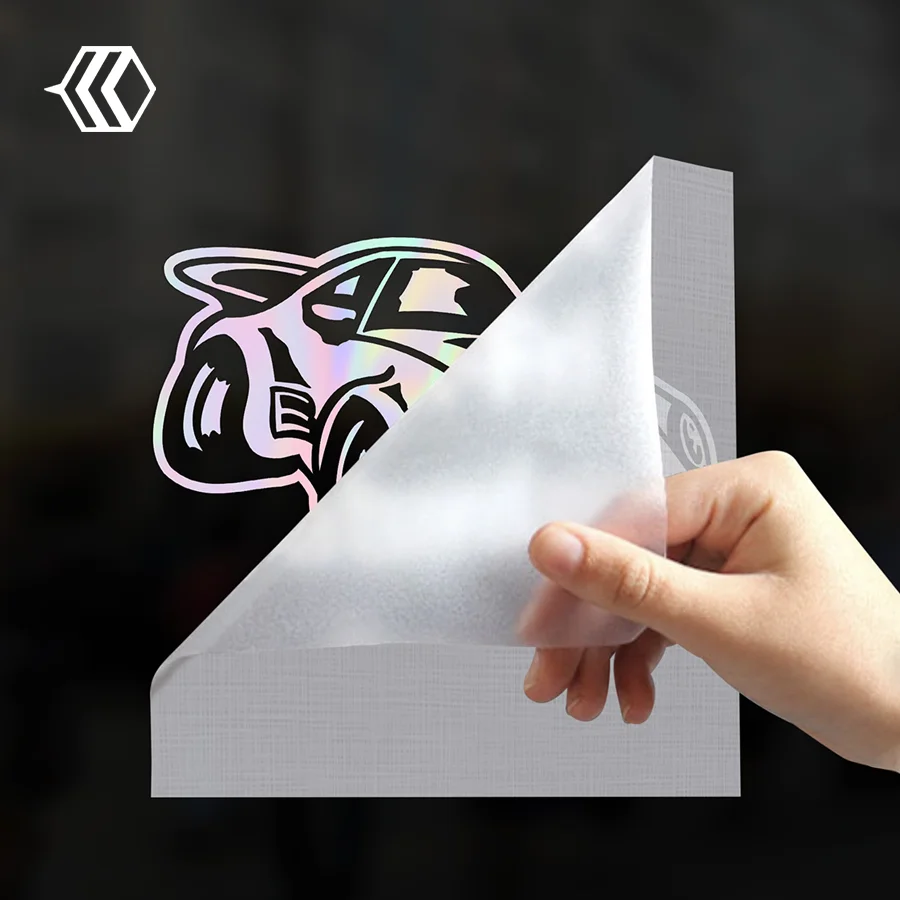

Are you looking for a low-cost, high-quality option to promote your brand? Our high-quality Transfer Stickers provide a sleek, 3D gloss finish using your original sticker design and artwork, which magically attaches to any desired surface while leaving no background or additional residue behind. Packaging Bee offers unique custom transfer stickers that you can use to personalize your things!

Custom transfer stickers make it simple to apply intricate, multi-part designs and logos to any surface. Our full-color customized stickers are ideal for personalizing your computer, beverage items, packaging, or vehicle. In addition, you don't have to worry about its quality because we only use durable and waterproof materials.

So, wait no more and grab your favorite stickers today at an affordable rate.