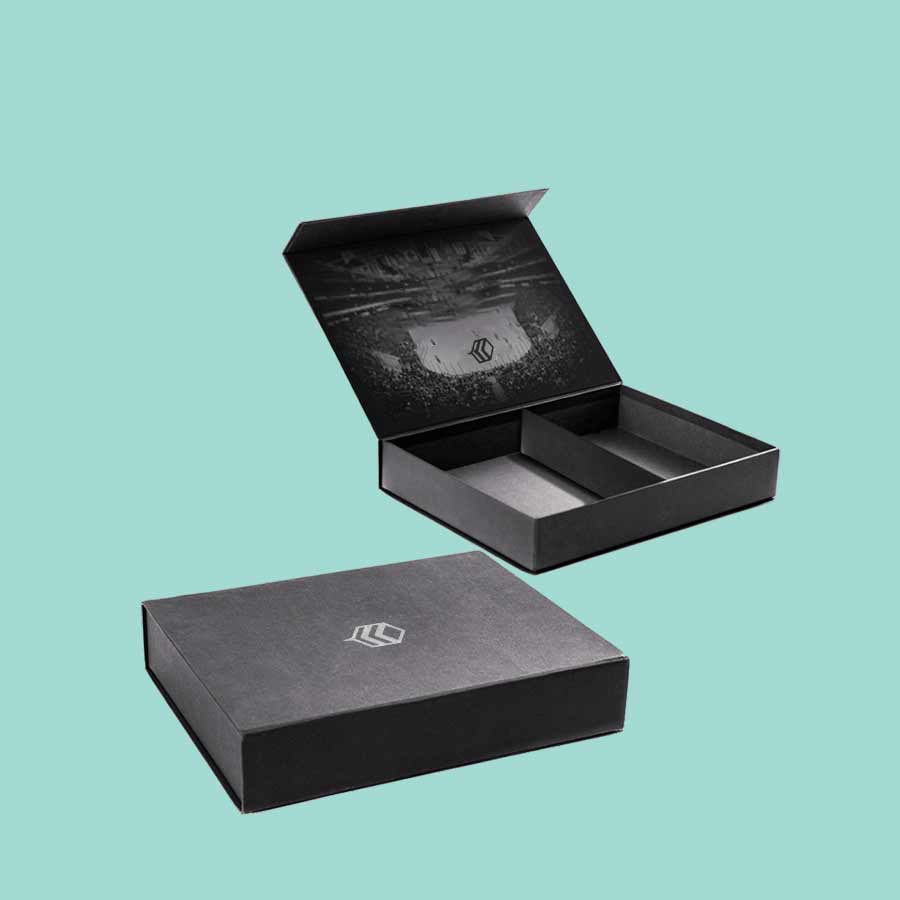

Look no further than Packaging Bee for creating rigid setup boxes that are sturdy, beautiful, and unique. At Packaging Bee, we make sure all your needs are well-catered for. Our custom rigid boxes are designed by keeping your needs in mind so your sales can soar as high as your ambitions!

We use high-quality materials for designing custom rigid boxes. To give the custom boxes a fine print quality, we use leading printing techniques available in the market. To provide truly personalized packaging to the customers, we offer various add-ons and finishing coats at affordable rates. You can use the sampling services to gauge the box's quality and design features before entering the mass production phase. Contact us today and create packaging that wow your customers!